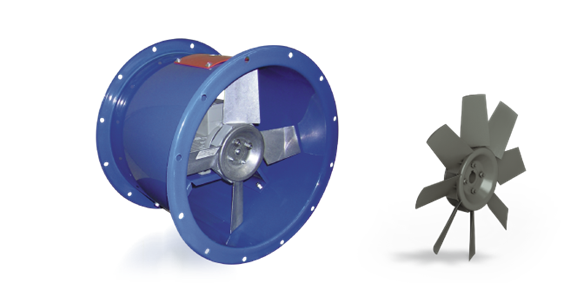

In the continuously developing and expanding industrial sector, adequate use of the means of making the air healthy both for the products produced and for the employees at work appears increasingly indispensable. Preserving certain environmental conditions is essential in order to develop, especially in the chemical field and related contexts, adequate final products. So produce yes, but also protect the health of those who find themselves having to carry out their tasks in closed environments on a daily basis and where it is therefore necessary to guarantee a certain degree of healthy air. In this case elements such as industrial fans come into play air extractors, also present for large volumes. Cylindrical air circulators, in particular, which can be of various types. So let's focus our attention on them and find out more about the models and choice of the best ones currently on the market.

Types of air circulators

As announced in the introduction, there are various types of industrial fans, also known as circulators or air extractors. Essential elements in companies, especially those in contact with chemical products, to make the environment in which they operate healthy. That is both to protect the health of employees and to maintain stable conditions for production purposes. Just think of the pharmacological and similar fields to understand how fundamental all this is for the purpose of production. There are therefore various models of air circulators: from cylindrical to axial, through to models that can be fixed to the external industrial roof and so on. In short, a wide range of tools that can be used for installation inside or outside an industry and make it capable of cleaning the air and making it circulate properly to preserve workers' health and environmental production conditions.

Intended use of air circulators

Obviously when we talk about types of air circulators everything must be contextualized and also related to the relative intended use of the same. In fact, depending on the environment to be "cleaned" or "cooled", a specific model or ventilation, recirculation system etc. is chosen. For example there are i industrial car parks, or even chemical companies, not to mention fire-fighting structures, where each of the aforementioned requires a specific type of circulator. Space-saving axles, to name one model, are more suitable for car parks; those with ducts or rings are more suitable for installation in industrial warehouses and therefore relating to the production sector.

Resistance and longevity over time

Two of the most popular features of industrial fans and therefore also of air circulators are certainly the resistance of the constituent materials, and the durability over time, in particular of the AF series that we have available on the our site. In fact, these tools, which are so useful for cooling or cleaning environmental production air, have their home advantage precisely in temporal resilience. This allows them to have little need for maintenance other than annually for routine checks. An aspect of no small importance for those who have the task of monitoring and, if necessary, replacing the aforementioned company elements.

Guide to choosing the best air circulator models

After having reviewed all the various information regarding air circulators and more generally industrial fans, we now come to the main topic: that is, the guide to choosing the best models currently available on the market. First of all, it is necessary to distinguish the material to be removed through purification: therefore whether it is micro dust, oily mists, dust from dry processing, dust from flammable materials or from the production of precious metals. Each of the mentioned processes involves a different pollutant that must be cleaned through the use of air circulators. The cylindrical ones represent the best weapon against these pollutants which make the working environment harmful both for the employees and for the final yield of the product. Once the nature of the air pathogen is understood, we move on to the selection of ventilation and recirculation models. In this sense, there are three main models ranging from 18 to 26''. The latter are equipped with an aerodynamic aluminum fan to significantly reduce noise. Therefore not only functionality but also minimal noise emissions which do not impact the ideal processing conditions. Extremely simple both to install and maintain, these circulators are also made with galvanized or stainless steel bodies for maximum resistance to corrosion.

Do you need more information? Go to the appropriate one contact section to book your consultation!