The industrial sector is a world made up of various elements that, when combined, ensure the development of a product. There are many productive fields, from food to mechanics, from metal processing to the processing of materials that make up objects functional for everyday life. However, regardless of the final result, the production chain revolves around tools among which we also find the extraction tower. torrino di estrazioneLet's see what it is and how this component represents a necessary element in certain companies. So, characterization and purpose of what in many cases is much more than a mere extractor.

What is an extraction tower

After making a necessary introduction to the topic, let's first examine the meaning of the term in question: the extraction tower. This term refers to a system used in industries for the low-pressure suction of certain volumes of air. This component is often noticed at first glance but many are unaware that it is defined in this way. To put it simply and less technically, the extraction tower is nothing more than that mushroom-shaped object that is usually connected to flues or more or less complex suction systems. It is placed on the roof of a structure to convey a certain volume of low-pressure air from the inside to the outside. Therefore, as anticipated in the introductory phase, it is a very useful element, especially when talking about chemical companies or those in contact with similar materials. Here, air filtration is fundamental both for preserving the environmental working conditions and for the protection of workers, and not just for the final product. This discussion helps us understand how this industrial component, often ignored, is actually crucial for maintaining certain environmental conditions inside a workplace. Just like its placement, the extraction tower is at the pinnacle of functionality, not just in material installation. It is the extreme point of a production chain that would otherwise be unable to fulfill its task.

Composition of the extraction tower

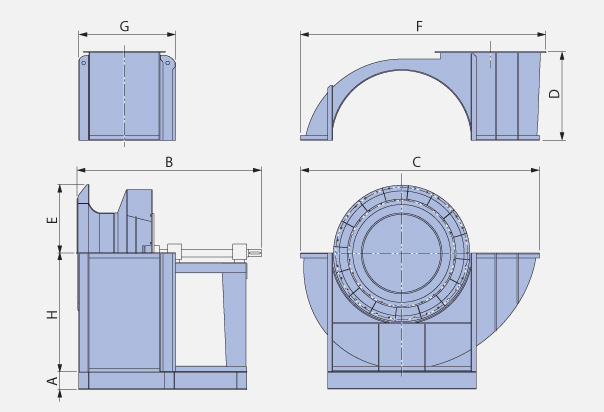

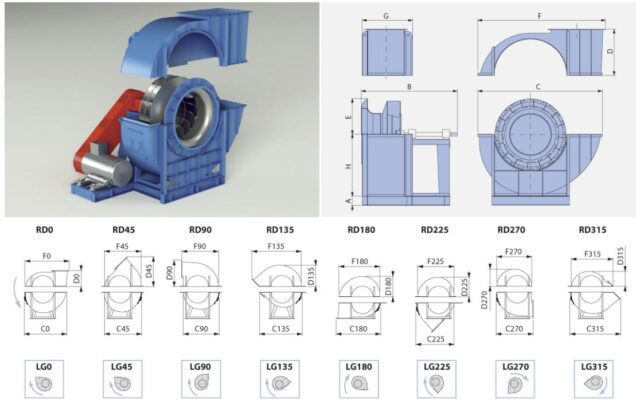

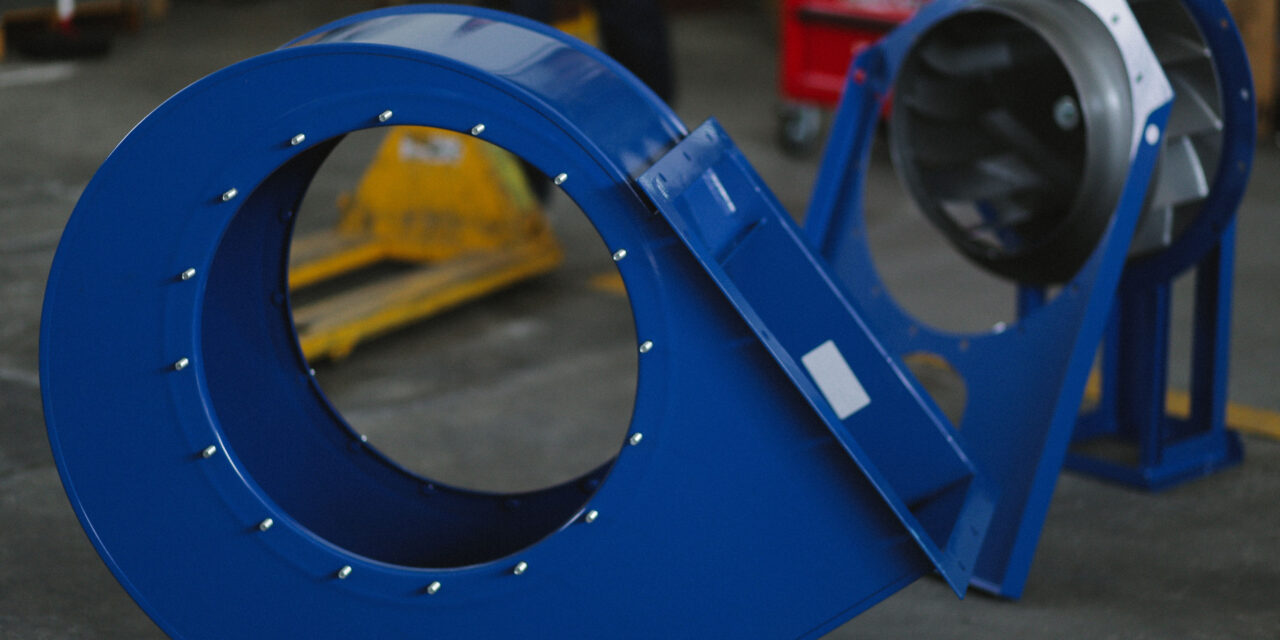

Having understood what the extraction tower is and particularly the context of its application, let's now shift our focus to its composition. Alvanized steel and glass in back resin are the two main components of the aforementioned object. These materials are used to make the dome and the part immediately below it functional for protection against atmospheric agents. Inside, there is a motor of varying power that drives a fan useful for air suction. This is very quiet during operation, contrary to what one might think. In fact, when thinking of an industry, the immediate thought is often of the noise and chaos from which workers have to isolate themselves using specific acoustic protection devices.

The range of extraction towers

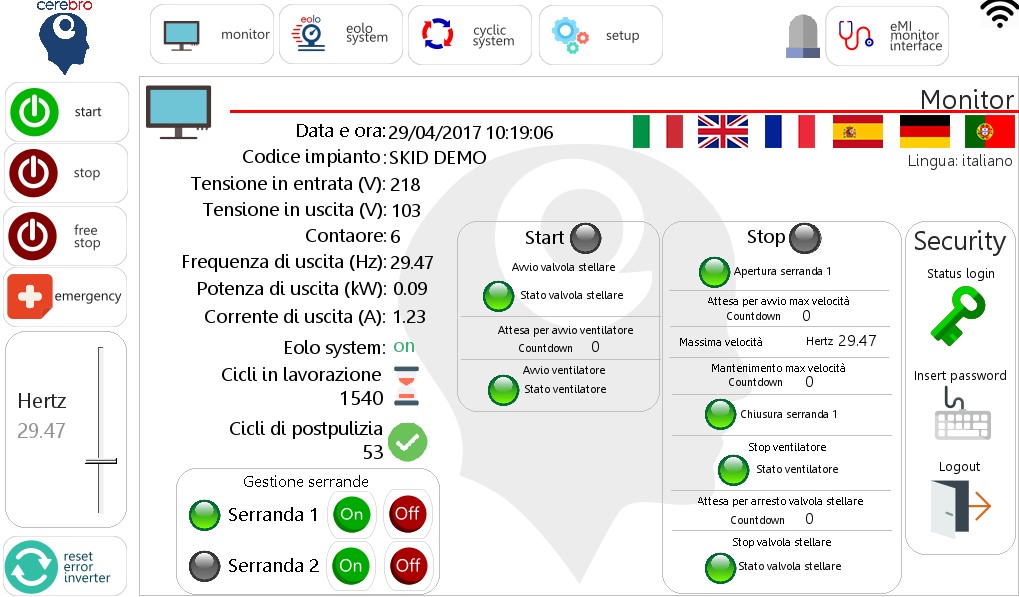

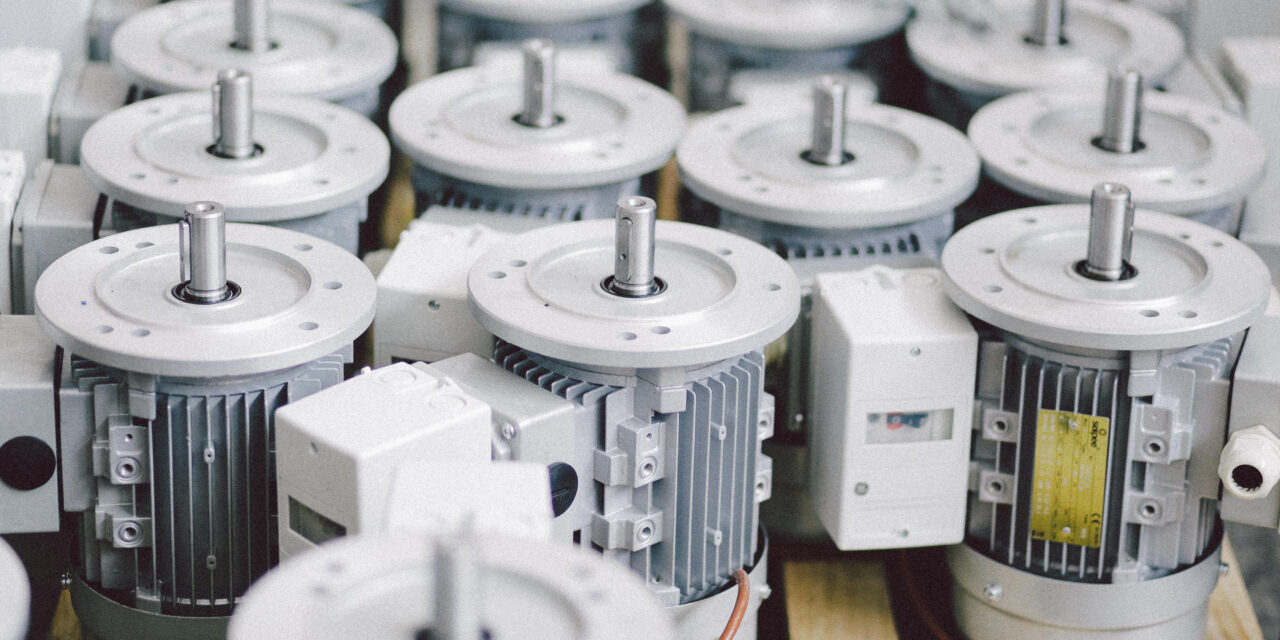

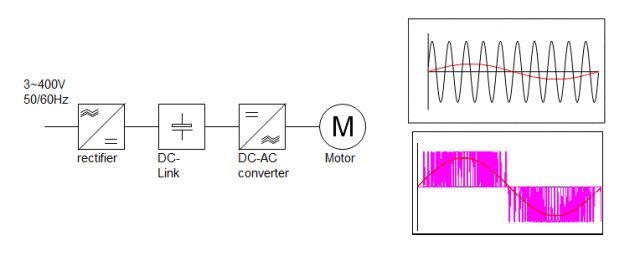

There is a wide range of extraction towers, which you can also find on our websitediffering mainly in the power of the suction motor. There are nine different models of motors, all three-phase, providing significant drawing and subsequent filtering power. Alternatively, there are also single-phase models equipped with variable speed controllers to regulate the air flow. Depending on its characteristics, the extraction tower can operate up to a maximum temperature of 200 degrees. Such delicate operating conditions can only be sustained by materials like steel and zinc. In fact, the extraction tower is a component specifically designed as explained above to operate without any problems under the mentioned conditions.

Other technical features of the extraction tower

Let's now examine other technical features of the extraction tower, in addition to those listed so far. Among these, we find a proportional weight-to-size ratio conducive to proper functioning. This also greatly facilitates its mounting on roofs and tops of structures of interest. Indeed, the lightness of the component in question is aimed not only at its use but also at its insertion and relative installation. This factor also makes the extraction tower an extremely long-lasting element. It can last many years due to the galvanized and steel coating between the inner and outer parts. This aspect also has a positive impact on the economic side, as such exquisite manufacturing does not entail additional maintenance costs.The fan housed inside is perfectly stabilized to ensure there are no oscillations or unexpected movements. The motor powering it, being of great power in the vast majority of models, drives the fan at a high speed. This would affect the correct aspiration process if the aforementioned fan were not balanced. Not to mention the further impact on the quietness of the suction mechanism, always related to stabilization. In short, from what can be gleaned about the characterization and constitution of the tower, we are undoubtedly talking about a tool of artisanal excellence. A component that is made and designed not only for the task it must perform, but also for the protection and safeguarding of its usage conditions. The better the quality of its parts (motor, fan, etc.), the more likely it is to withstand the years. All this without having to resort to corrective and maintenance interventions, which are often not only costly but also invasive and not entirely effective. The extraction tower is therefore a key object in various types of industrial production, as it represents not just a mere air filtration and suction system, but an indispensable means for the protection of a work environment. Especially when the latter involves materials or chemical compounds, often releasing residues and fumes that absolutely need to be evacuated.

Are you the owner of a company and need a range of industrial products? Discover our product list and fill out the contact form! nostri prodotti e compila il form contatti!