As a rule, fans are sized and installed according to maximum ventilation requirements, but maximum ventilation capacity is not always necessary, as the installation of an inverter allows the speed of the fan motor to be controlled to meet actual ventilation needs. Reducing the motor speed reduces the amount of energy needed to power it (up to 8 times), which in turn reduces costs and consequently co2 emissions.

When connected to a sensor system, inverters can be even more effective by controlling motor performance according to any number of predefined settings such as temperature, flow, humidity, etc., eliminating the need for manual adjustment.

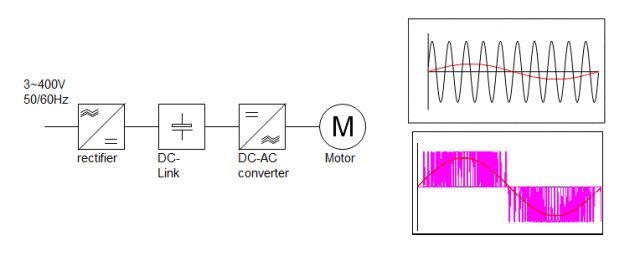

How does an inverter work?

Frequency manipulation with an inverter consists of converting the incoming mains voltage from AC to DC using a full-wave rectifier circuit. There is then a second DC link stage that smooths out the waveform and ensures that the inverter remains charged while in use. The final stage involves creating a pulsed square-wave voltage output to simulate an AC waveform as shown below:

Inverters can play a key role in energy-saving projects, but the benefits do not stop there. Reducing the amount of time the motor runs at full speed will not only save energy, but also reduce the strain on the motor itself and any connected components. This means less maintenance requirements and, once again, a reduction in costs. Installing an inverter on an older system that is prone to wear and tear can even help extend its service life.

Discover the entire line of Invertek Drives that can be coupled to a new or existing ventilation system in your company, click here.

Download the APP to calculate your savings NOW!